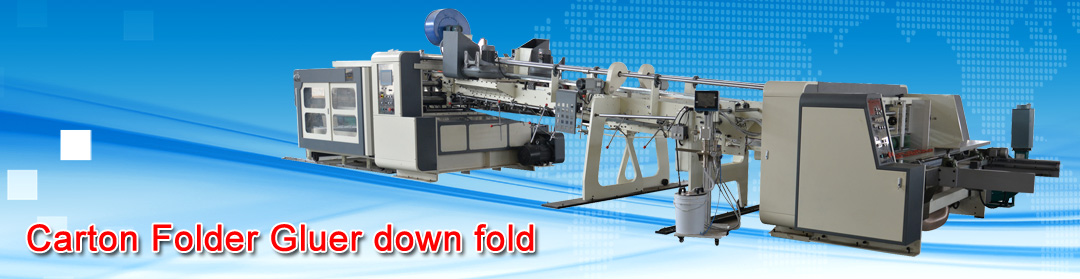

MJZXJ-1A Folder Gluer with inline Strapping

Introduction of the machine:

MJZXJ-1 model Automatic Folder gluer machine is composed of feeding part, glue and folding part, stacker part, speed controlled by PLC, paper width is adjusted by Touch PC, machine operation is easy and accurate, machine with automatic paper feeding function, automatic glue and fold function, automatic counting, automatic stacking and double conversion operation, the normal speed is 160pcs/min, Max. speed can be 220 pcs/min, this machine is your best choose which is energy-efficient and environmental protection.

Function and characteristic:

1. Automatic carton folding and at same time to finish the tape paste which is save time and labor force

2. Can be used for different size cartons and size adjust is simple and fast.

3. Machine run is stable and reliable, packing result is strong and nice.

4. Machine operation is simple and easy for maintenance.

5. Automatic collimator angle, 180 degree correction, effective corrective the carton appear fork and tail phenomenon.

The product structure:

1. Control Panel:

Touch Screen Input operation is easy, machine adopt PLC controller, digital operate, touch screen input which can change date or speed or others without stop machine, machine can be auto-feed paperboard, auto-folding, auto-counting and auto-stacking output, normal speed is 160pcs/min and Max. speed is 220 pcs/min.

2. Feeding part

1)Paperboard height adjustment part is adopt high quality steel, can quick adjust different specification cartons, such as height and length.

2)The suction belt of feeding part adopts the high-tech materials, tension layer seamless joint the girdle which protect machine everything well in running.

3)Suction motor and main motor of feeding part adopts Taiwan brand which is high stability.

4)Adopt the high quality electromagnetic clutch and brake system so that make feeding part can be single paper or continuous operation which effective control the paperboard waste and output precision.

5)Pat part of feeding has effective reduce error of manual operation and improve the stability of paper feed.

3. Folding and gluing part:

1. Motor adopt European brand, with function of stability, speed adjustment speedy and without noise pollution

2. Seamless joint ring conveyor belt of folding part adopt imported special material which is high friction and high wear-resisting, can finish automatic folding accurately

3. Gluing part adopt high quality stainless steel gluing wheels, glue coated evenly、and can efficient to save glue.

4. Folding part equipped with single channel creasing correction and six coining device which can precision and efficient to correct paperboard’s pressing line deviation and make carton finish folding accurately.

4. Correction stacking output part:

1. Stacking part has functions of auto-counting, stack neatly and stacking output, customer can set the output number of cartons by himself.

2. Automatic correction, stepless speed variator correction, automatic correct non-standard cartons.

5. Parts introduction:

1) Machine is 380V/AC, power is 11.5kw, energy conservation and high efficiency.

2) PLC computer components、frequency components and electric appliance all adopt high quality imported components.

3) Belt adopts Italy ring and seamless belt.

4) Bearing adopt famous brand “TR bearing”

5) Spiral screw、lead screw and nut all adopt 45# stainless steel with quench treatment.

6) Screw nut adopt high quality copper (ZQSn10-1), wear-resisting and durable, long life and drive precision is high.

7) Copper bush(ZQSn6-6-3) with oil lubrication, wear-resisting and durable

8) Machine is controlled by wireless remote device, can adjust paper size speedy and conveniently

6. Machine parameters: (Total 8tons)

|

Model MJZXJ-1 |

8020 |

1024 |

1224 |

1424 |

|

Max. Size |

800*2000mm |

1000*2400mm |

1200*2400mm |

1400*2400mm |

|

Min. Size |

170*470mm |

260*650mm |

260*650mm |

260*650mm |

|

Installation area |

3200*11500mm |

3400*12500mm |

3600*12500mm |

3800*13500mm |

|

Power Required |

15.0KW |

15.0KW |

15.0KW |

15.0KW |

|

Max. Working Speed |

220m/min |

220m/min |

220m/min |

220m/min |

|

Normal working Speed |

200m/min |

200m/min |

200m/min |

200/min |

|

Machine Weight |

6800kg |

7500kg |

7500kg |

8000kg |

Note: If you need any other size, kindly feel free to let us know. We can make the machine based on your sizes.

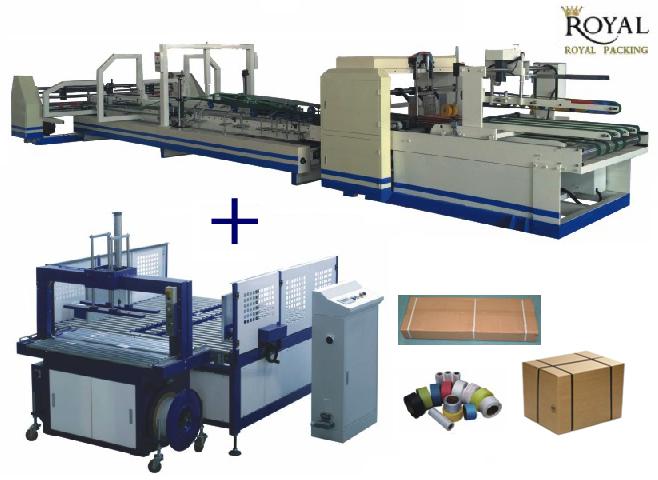

Automatic strapping system for corrugated carton

|

Item |

Specification |

|

Power Supply |

1Phase/AC220V/50/60HZ/2.4kW,12A |

|

Packing Speed |

15 package/minute |

|

Tension Force |

0-45kg |

|

Hot-adhering Position |

Bottom |

|

Table Height |

920mm |

|

Weight Capability |

80kg |

|

Arch |

Standard Size: Width1250mm X Height 500mm (inner size) Material: Iron arch (It’s possible to customize size, ≥W1050 ) Customer-made size W1650 x H 500mm |

|

Applicable PP Strap |

Width 5mm,6mm Thickness(0.5-0.8)mm(to be specified) |

|

Applicable PP Strap Spool |

Inner dia.:200mm~210mm, |

|

Packing Type |

Parallel 1~2 strap for optional |

|

Electrical Configuration |

PC board control +PLC control “SIEMENS” |

|

Machine Dimension (mm) |

L2040×W1190×H2100 |

|

Packing Measurement (mm) |

L2140×W1310×H2250 |

|

Weight (kg) |

N.W:380 G.W:440 |

|

Noise |

≤75DB |

|

Environment Condition |

Humidity≤98%, temperature 0-40℃ |

|

Bottom Adhesion |

surface≥90%,width≥20%, deviation of position≤2mm |

|

Optional |

Width 8mm,9mm |

Picture of turning-direction system:

Picture of squaring system