RYGT-3D Automatic Corrugated Box folder gluer

Introduction:

RYGT-3D Automatic Corrugated Box folder gluer series high speed automatic corrugated folder gluer are using imported electrics and parts, especially for export, able to pre-press the paper and have a better pasting effect ,able to pre-press the paper and have a better pasting effect ,also have a wide application ,this series have features like nice appearance ,high speed ,flexible adjustment ,big width range . Specially for making boxes from flute F,E,C,B like wine box ,carton box ,average speed 8000pcs/hr depends on different box size ,this series widely applied to wine factory carton factory and the other post press finishing ,this series save labor force by four fifths ,also reduce the glue by two thirds ,it’s preferred product for post-press finishing .

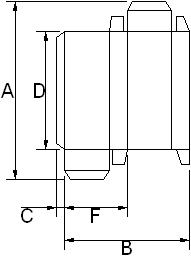

Main technical parameter:

RYGT-3D-1050

|

Type of boxes |

(Amax) |

(Amin) |

(Bmax) |

(Bmin) |

(Cmin) |

(Dmin) |

(Fmin) |

|

box |

1200mm |

150mm |

1050mm |

180mm |

12mm |

100mm |

81mm |

RYGT-3D -1250

|

Type of boxes |

(Amax) |

(Amin) |

(Bmax) |

(Bmin) |

(Cmin) |

(Dmin) |

(Fmin) |

|

box |

1200mm |

150mm |

1250mm |

180mm |

12mm |

100mm |

81mm |

RYGT-3D -1450

|

Type of boxes |

(Amax) |

(Amin) |

(Bmax) |

(Bmin) |

(Cmin) |

(Dmin) |

(Fmin) |

|

box |

1200mm |

150mm |

1450mm |

180mm |

12mm |

100mm |

81mm |

RYGT-3D -1650

|

Type of boxes |

(Amax) |

(Amin) |

(Bmax) |

(Bmin) |

(Cmin) |

(Dmin) |

(Fmin) |

|

box |

1200mm |

150mm |

1650mm |

180mm |

12mm |

100mm |

81mm |

RYGT-3D -1850

|

Type of boxes |

(Amax) |

(Amin) |

(Bmax) |

(Bmin) |

(Cmin) |

(Dmin) |

(Fmin) |

|

box |

1200mm |

150mm |

1850mm |

180mm |

12mm |

100mm |

81mm |

Characteristics

|

Linear velocity |

0~220m/min |

|

Suitable paper quality |

220~800g/m² cardpaper F flute and E flute paper |

|

Paste box basic form |

One size edge pastes ,two side edge pastes |

|

Feeding way |

Automatically and continuously feeding |

|

Adhesive |

Solute type |

|

Needed power |

AC380V 7 KW |

|

Weight |

2200KG |

|

Overall Size |

7500X1450(1650)(1850)×1300mm |

|

The scope of Count |

0~999999 |

Working principle:

After starting the machine, the automatic paper feeding table will feed the paper sheets needed to be pasted out one by one continuously. The gluing device will automatically coat the glue on the adhesive position of paper box evenly. The glued paper sheets also will automatically send to the fold part. In the course of paper sheets ahead, the belt device of the fold part will automatically fold and stick the paper box. After finishing the fold and adhesion, send the paper box to the pressing part. After pressing, send it to the conveying part to be pressed firmly, finally send it to the paper receiving table. The whole working procedure is finished.

Electrical configuration:

|

Order |

Name |

Specifications |

Quantity |

Note |

|

1 |

Control Switch |

LA10-3H 5A |

1 |

Sino |

|

2 |

Circuit Breaker |

TPB-2 |

1 |

Siemens (German) |

|

3 |

Relay switch |

BS211B |

2 |

Siemens (German) |

|

4 |

Intermediary relay |

RH2B-UAC220 |

1 |

Siemens (German) |

|

5 |

Button switch |

XB2BA45 |

2 |

IDEC (Japan) |

|

6 |

Button switch |

XB2BA35 |

3 |

IDEC (Japan) |

|

7 |

Optional switch |

XB2BD21 |

1 |

IDEC (Japan) |

|

8 |

Indicator light |

PL220V φ12-φ12.5 |

2 |

ATP |

|

9 |

Contact relay |

3TH8040 220V |

3 |

Siemens (German) |

|

10 |

21 terminal blocks |

TD15-21 |

21 |

|

|

11 |

21 terminal blocks |

TD15-19 |

19 |

|

|

12 |

Transformer BK100 |

Input 220V output 36V 24V |

1 |

Jindong |

|

13 |

Rectifier |

C1010 10A |

2 |

|

|

14 |

Three-hole socket16A |

LB-026 16A |

1 |

Longbang |

|

15 |

Three-pin plug |

10A |

1 |

|

|

16 |

Air switch |

2P16A |

1 |

Delixi |

|

17 |

Air switch |

3P16A |

1 |

Delixi |

|

18 |

Inverter |

5.5kw |

1 |

EASYDRIVE |

|

19 |

Inverter |

0.75kw |

1 |

EASYDRIVE |

Machine photos:

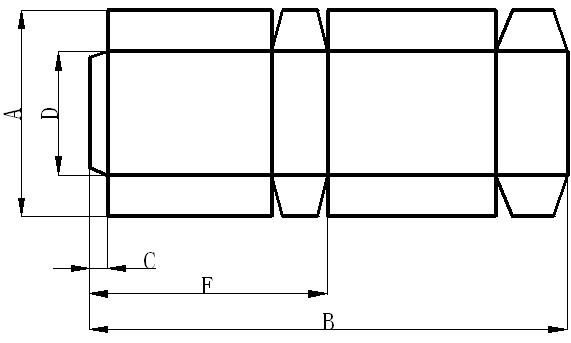

Sample Photos:

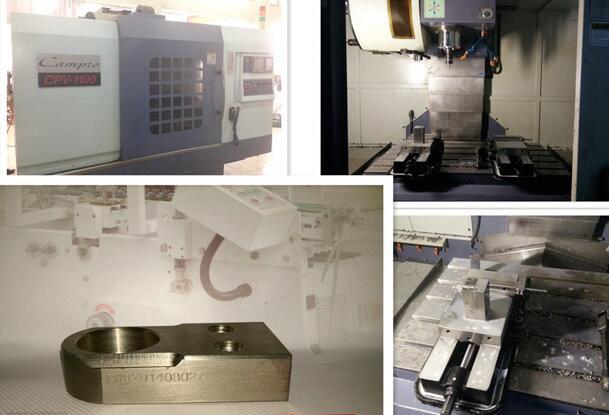

Processing Center

Package: