RYGT-2 Pre-Fold Folder Gluer Machine

Description:

RYGT-2 Pre-fold automatic high speed automatic folder gluer machine, In the pre-folding part, the first fold and the third fold can be exchanged by 180 degree and 150 degree. The second fold and the fourth fold can be molded in 180 degree, the special design is also available. Main parts of this machine are adopted import and domestic famous brand products, such as folding belt is adopted powerful rubber flat belt imported form Swiss, its service life is raised greatly, which is 10-20 times of common belt, Use of imported electrical appliances. Speed, reasonable structure, convenient and flexible operating characteristics .It is suitable for the paste process, such as the wine box, cosmetic box wine boxes CD boxes Document boxes and French fry box etc .

Characteristics

1. The partial paper feeding adopt the monomer structure, it is extremely convenient to move the assemble and disassemble.

2. Adopt the integral sealed glue box, so as to make glue not easy to evaporate, move conveniently.

3. The move row adopts the two-way screw rod to adjust, fast and simple.

4. The transmission adopts the synchronous belt and mast top, accurate, ensure to paste box perfect quality.

5. Pre-folded function can develop the production efficiency, forma complete set with the automation packing.

6. The press and delivery part can move front and back, so as to provide the convenience to wine box and long box.

7. The photo electricity count and automatic kick board are assort, accurate and convenience.

2. Main technical parameter:

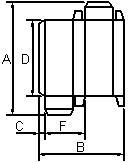

RYGT-2-800

|

Type of boxes |

(Amax) |

(Amin) |

(Bmax) |

(Bmin) |

(Cmin) |

(Dmin) |

(Fmin) |

|

box |

700mm |

70mm |

600mm |

110mm |

8mm |

70mm |

51mm |

RYGT-2-1200

|

Type of boxes |

(Amax) |

(Amin) |

(Bmax) |

(Bmin) |

(Cmin) |

(Dmin) |

(Fmin) |

|

box |

700mm |

70mm |

800mm |

110mm |

8mm |

70mm |

51mm |

|

Linear velocity |

0~220m/min |

|

Suitable paper quality |

220~800g/m² cardpaper |

|

Paste box basic form |

Both side are folded , both sides are Pre-folded, One-side edge pastes. |

|

Feeding way |

Automatically and continuously feeding |

|

Adhesive |

Solute type |

|

Needed power |

AC220V 3.5 KW |

|

Weight |

2100KG |

|

Overall Size |

7200×1100(1300)×1300mm |

|

The scope of Count |

0~999999 |

Electrical configuration

|

No. |

Name |

Specifications |

Qty |

Note |

|

1 |

Control Switch |

LA10-3H 5A |

1 |

Sino |

|

2 |

Debuy Switch |

TPB-2 |

1 |

Tiande |

|

3 |

grinding switch |

BS211B |

2 |

|

|

4 |

Limit switch |

JLXK1-511 |

1 |

Tianzheng |

|

5 |

Button switch |

XB2BA45 |

2 |

Schneider(France) |

|

6 |

Button switch |

XB2BA35 |

3 |

Schneider(France) |

|

7 |

Optional switch |

XB2BD21 |

1 |

Schneider(France) |

|

8 |

Indicator light |

PL220V φ12-φ12.5 |

2 |

ATP |

|

9 |

contactor |

3TH8040 220V |

3 |

Siemens (German) |

|

10 |

21 terminal blocks |

TD15-21 |

21 |

|

|

11 |

21 terminal blocks |

TD15-19 |

19 |

|

|

12 |

Transformer BK100 |

Input 220V output 36V 24V |

1 |

Jindong |

|

13 |

Rectifier |

C1010 10A |

2 |

|

|

14 |

Three-hole socket16A |

LB-026 16A |

1 |

Longbang |

|

15 |

Three-pin plug |

10A |

1 |

|

|

16 |

Air switch |

2P16A |

1 |

Delixi |

|

17 |

Air switch |

3P16A |

1 |

Delixi |

|

18 |

Inverter |

3.5kw |

1 |

Schneider(France) |

Machine photos:

.jpg)

Sample Photos:

Processing Photos:

Packing photos: